-

© Haymarket Media

© Haymarket Media -

© Hyundai

© Hyundai -

© Haymarket Media

© Haymarket Media -

© Storedot

© Storedot -

© Haymarket Media

© Haymarket Media -

© Haymarket Media

© Haymarket Media -

© Haymarket Media

© Haymarket Media -

© Haymarket Media

© Haymarket Media -

© Mineral Resources - Mt Marion

© Mineral Resources - Mt Marion -

© Mineral Resources - Mt Marion

© Mineral Resources - Mt Marion -

©

© -

© Polestar

© Polestar -

© Volkswagen

© Volkswagen -

© Jaguar

© Jaguar -

© Nissan

© Nissan -

© Haymarket Media

© Haymarket Media -

© Haymarket Media

© Haymarket Media -

© Haymarket

© Haymarket

-

When electric cars first entered the market, the battery powering the electric motor was much smaller and less efficient than the units fitted to EVs today.

For example, the 2010 Nissan Leaf launched with a 24kWh battery. Nowadays, electric cars are far more advanced and often feature larger batteries with a huge capacity – the Volkswagen ID 3 has a 77kWh battery, the Mercedes EQS SUV has a huge 118kWh unit, and the GMC Hummer EV a colossal 247kWh.

-

An EV battery is not too dissimilar to the one you’ll find in the back of your phone or laptop, except it's much larger, more durable and can handle greater changes in temperature.

Much like a smartphone, the battery in an EV loses capacity and eventually reaches the end of its life. However, that life is far longer than a smartphone’s; an EV battery normally lasts between 10-20 years.

But what happens to an electric car battery when it comes to the end of its lifecycle? Here, we take a look at how electric car batteries are made, what materials they use, how the pack can be recycled and repurposed, and if they are really as bad for the environment as some people say they are.

-

What is an EV battery made from?

The vast majority of electric cars use lithium-ion batteries that have four main components: a cathode, anode, electrolyte and separator.

These components allow electrochemical reactions to occur inside the battery creating the power that is sent to the electric motor that drives the wheels.

-

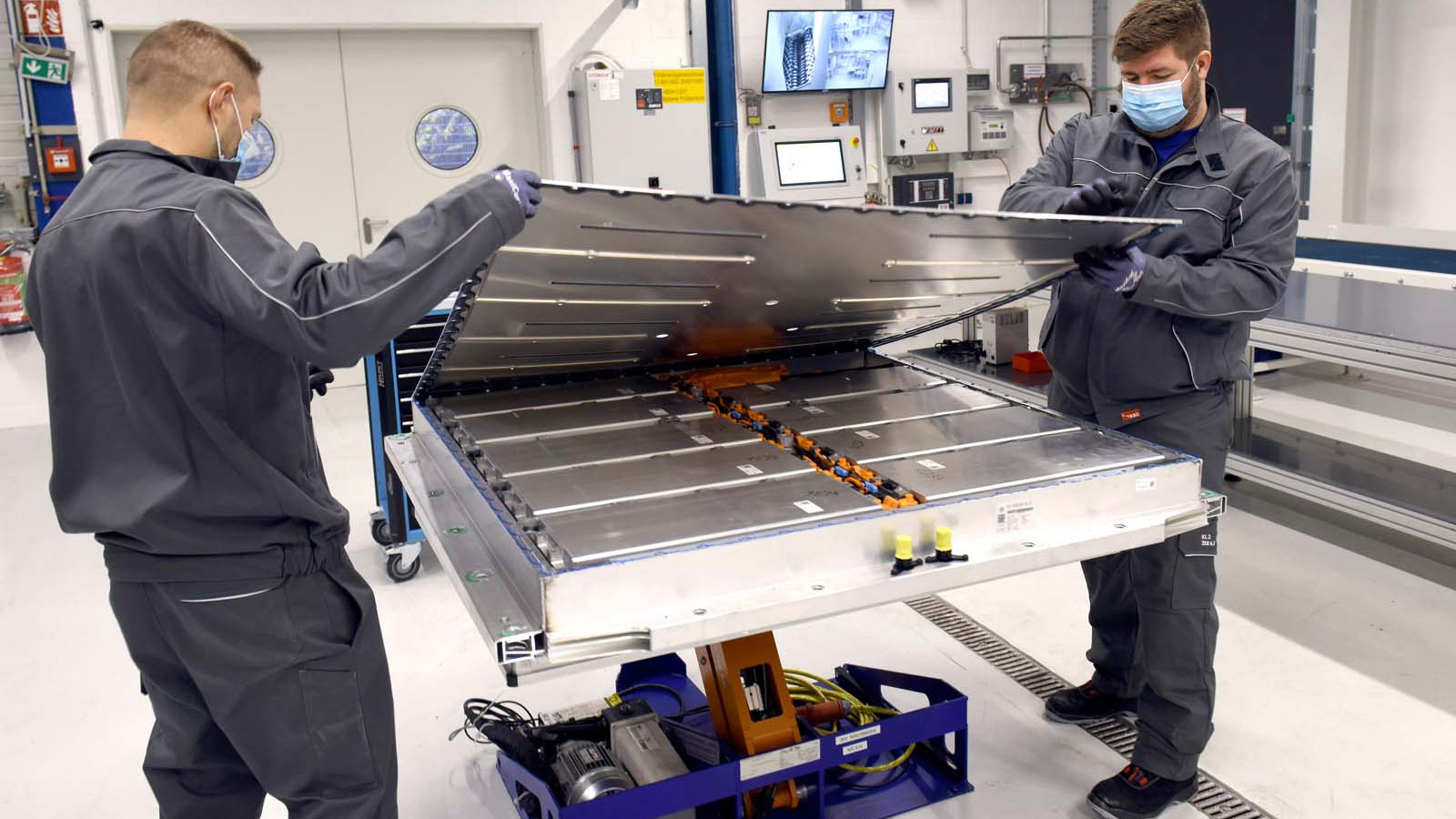

An electric car battery isn’t just one big unit, though. It consists of hundreds of cells grouped together to create a module which are then put together to create a battery pack.

Typically, the more cells an EV battery has, the greater its capacity, thus the further it can travel on a charge.

-

A BMW i4, for example, uses an 83.9kWh battery which is made up of four modules with 72 cells, and three modules with 12 cells.

As well as lithium, electric car batteries use expensive materials such as cobalt, manganese and nickel. Steel and aluminium are often used as part of the battery casing.

-

How long does an EV battery last?

The life expectancy of an EV battery varies depending on its size and type, but typically, a lithium-ion battery should last around 10-20 years or at least 100,000 miles (160,000 km).

Most EVs can achieve more than 100,000 miles before the battery needs changing. You hardly need to search to find a high-mileage EV that has covered well over 100,000 miles (160,000 km). Tesla themselves state that their batteries can last up to 150,000 miles (240,000 km) without issue.

-

Over time, the lithium-ion cells within the battery degrade after hundreds of charging cycles. In fact, an EV battery can lose as much as 2% of its battery capacity every year.

And while battery degradation won’t impact the performance capabilities of an EV, it will reduce the range.

-

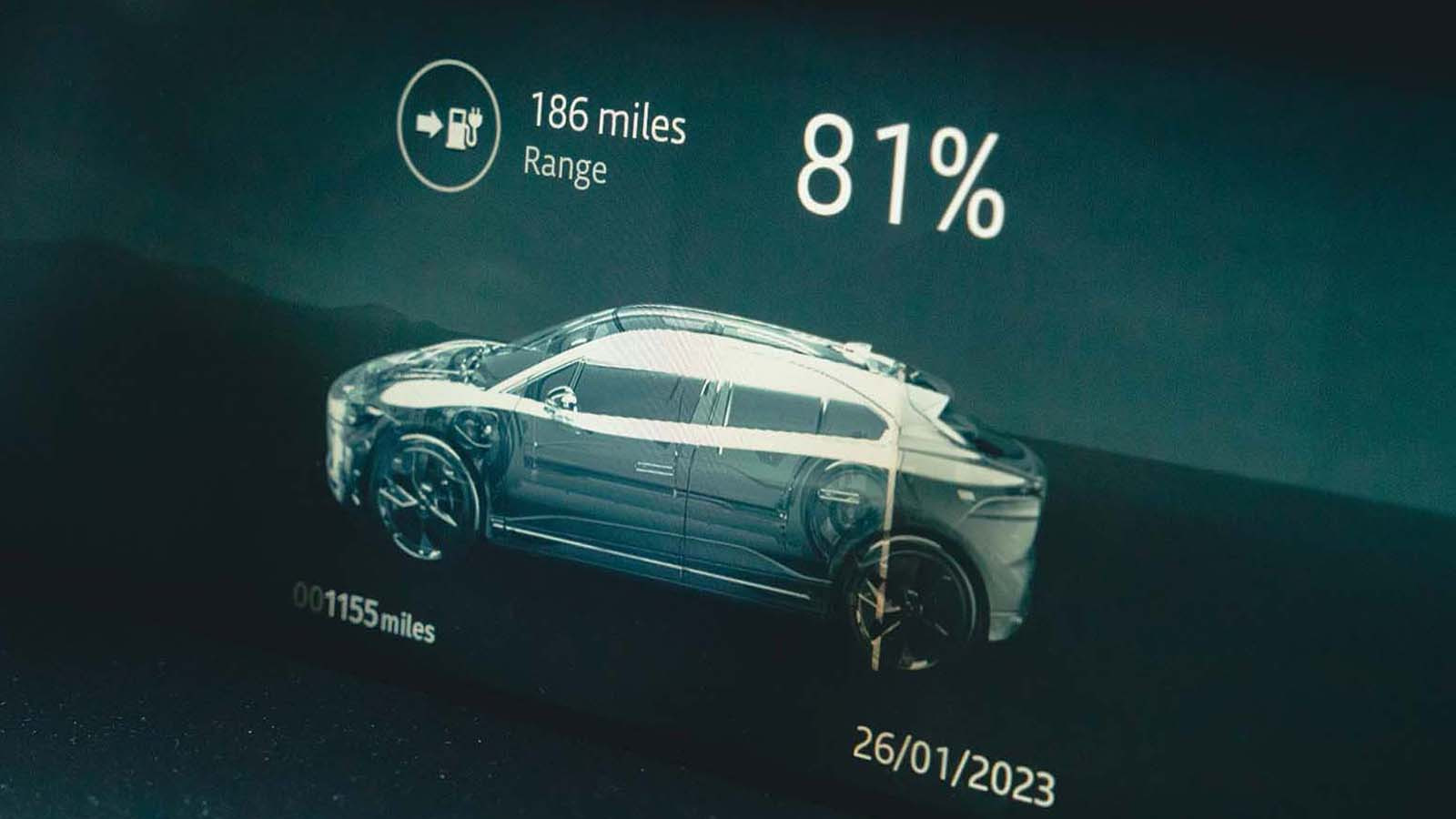

EV charging point

There are many ways EV owners can limit battery wear: only charging to 80% is common practice for most, consistently charging to 100% will degrade the battery faster.

DC rapid chargers – while handy for topping up quickly on the move – also causes greater wear due to their higher output speeds. Charging at a slower rate, for example using a 7kW home charger, is better for battery health.

Preserving battery health is important, too, as the cost to replace a full pack is expensive. And the bigger the battery, the more it will cost to replace.

-

What are the environmental impacts of EV battery production?

The precious metals required to make an EV battery are often mined through complex and costly processes – and there are a number of environmental impacts which come as a result of extracting materials such as lithium and cobalt.

-

Lithium mining is a highly water intensive process and it is estimated that around two million tonnes of water is required to extract one tonne of lithium, according to a United Nations study.

In fact, in places such as Chile, where lithium is commonly mined, more than half of the region's water is used for lithium extraction.

-

Mining for metals like nickel and cobalt has a number of impacts, too. In the Democratic Republic of the Congo - where huge amounts of cobalt are mined every day - ecosystems have been destroyed, land has degraded and there has been a huge increase in air and water pollution.

Nickel mines in the Philippines were closed in a bid to assuage the environmental damage caused by the process.

-

The entire EV manufacturing process also generates large amounts of CO2: Polestar revealed that building one of its 2 saloons creates 24 tonnes of CO2e (CO2 equivalents), while an ICE-powered Volvo XC40 generates 14 tonnes of CO2e during its production.

Of course, when an EV leaves the factory, it produces zero tailpipe emissions, whereas a petrol or diesel car continues to produce CO2. It is worth noting, however, that an EV has to travel a significant distance to offset the emissions produced during production.

-

Can an electric car battery be recycled?

The good news is that most of the materials used to create a lithium-ion battery can be recycled and the cells inside the pack can be reused for other purposes.

Vehicle manufacturers are able to recycle up to 90% of the materials inside the battery packs. Metals like lithium, nickel, cobalt and manganese can all be recycled and then reused in battery production once they have been chemically processed.

The recycling process itself is complicated: batteries need to be fully discharged to prevent any electric shocks during the dismantling of the pack. Batteries are then shredded in order to separate the materials inside.

-

Beyond the materials, individual cells can be recycled and used in other capacities. Jaguar, for example, partnered with generator manufacturer Pramac to develop a portable energy storage unit powered by second-life I-Pace batteries. Cells were taken from I-Pace prototype vehicles and then implemented into the energy storage system.

-

Nissan is also repurposing old Leaf batteries and using the cells to create portable power packs which can be used to power small gadgets and appliances.

-

Why is the recycling of EV batteries so important?

As we have mentioned earlier, mining raw materials like nickel, cobalt and lithium is highly damaging to the environment, not to mention expensive and complex.

By recycling a battery and utilising its materials and cells for another purpose will lessen the need for new raw materials. And not only does battery recycling put materials back into the supply change, it also reduces the impact on the environment, because less batteries are sent to landfill sites.

-

Governments and international organisations are recognising the importance of battery recycling and have introduced new regulations to make batteries more sustainable.

The European Union, for example, announced last year that from 2027, EV battery manufacturers will need to recover 90% of the nickel and cobalt used inside, and up to 95% from 2031.

Manufacturers will also need to recoup 50% of the lithium used from 2027, increasing to 80% in 2031.

-

The conclusion:

Electric car production is more costly for the environment than it would be to build a traditional petrol- or diesel-powered car.

However, over the lifetime of a vehicle the zero tailpipe emissions mean that an electric car will produce less cumulative emissions, and this can be reduced even further by charging our cars with renewable energy and building them using more efficient manufacturing processes.

And by recycling electric cars in their entirety, including their batteries, we can remove the potential impact they may have on the environment after their useful life in a car.